The installation of steel structure building is the course from setting up the steel columns until the finish of roof & wall panels and windows, doors, and finally meet the functional requirements of the building. The installation of steel structure building and other kinds of construction usually proceeded by a professional construction contractor, because there are several professional works, multiple kinds of equipment, and most important — the construction experience.

Why More And More People Want To Know The Installation of Steel Structure Building?

In the later years, as the steel structure building has simple structure, fast installation, cost economy, and some other obvious advantages(see more here: The advantages & disadvantages of steel structure buildings), more and more people try their building with steel structure. And for some reason, more and more companies and individual people take part in the process of the lifetime of steel structure building, from design to installation and maintenance. This is good news also bad news, the good news is that more and more people know the advantage of the steel structure building, and the bad news is that the installation is a bit of hard for the newcomers.

Is The Installation of Steel Structure Building Hard?

Compare with the professional construction contractor, companies and people who in need of steel structure building have distinct disadvantages in experience, staff, equipment, and some other aspects, so frankly speaking, to accomplish the installation of steel structure building is a little bit difficult to the newcomers of the construction industry.

To help them and also try to let more people know more about steel structure building, let’s take an example for the installation of steel structure building.

Procedure Of The Installation Of The Steel Structure Building:

- Prepare Before The Installation Of Steel Structure Building

- Inspect Before The Installation Of Steel Structure Building

- Column Installation – The Installation Of Steel Structure Building

- Steel Beam Installation- The Installation Of Steel Structure Building

- Bracing System Installation – The Installation Of Steel Structure Building

- Crane Installation- The Installation Of Steel Structure Building

- Overhead Crane Installation – The Installation Of Steel Structure Building

- Wall Purlin Installation- The Installation Of Steel Structure Building

- Roof Purlin Installation – The Installation Of Steel Structure Building

- Wall Panel Installation- The Installation Of Steel Structure Building

- Gutter Installation- The Installation Of Steel Structure Building

- Roof Panel Installation – The Installation Of Steel Structure Building

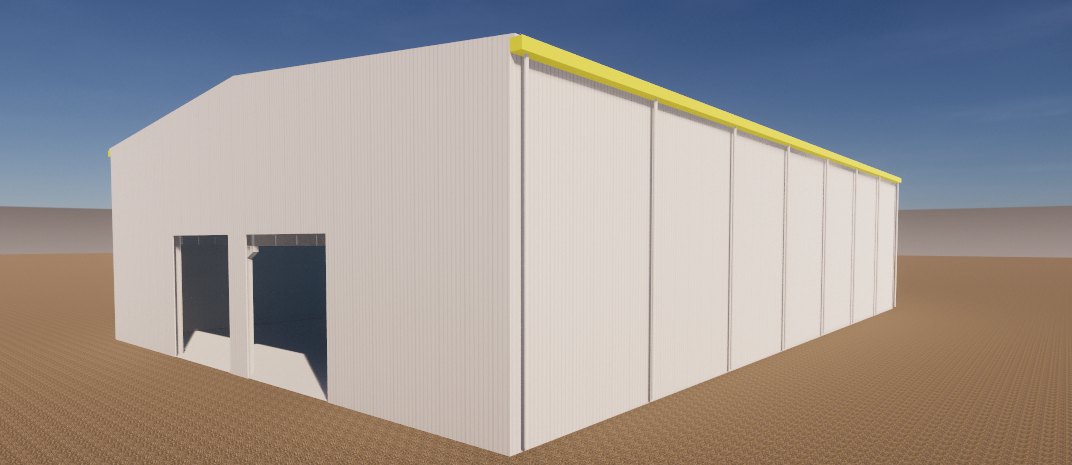

The Example: A Small But Complete Workshop

Here are the specifications about this workshop:

- Dimensions(L*W*H): 41*16*8.8-10.5m

- Slope: scale 1:10, single

- Crane: 5 Tons overhead crane

- Mainframe structure: welded H beams, materials Q355 steel, hot-dip galvanization 275g/㎡

- Secondary structure: steel bar, steel pipe, angle steel, steel plate, Q235 steel, thermal spray zinc 60g/㎡

- Door: electrical rolling door, 5*5m(W*H), with remote control

- Windows: PVC frame windows, 5mm clear glass, 4*1.3m(W*H)

- Entrance door: steel frame & door leaf, 0.9*2.1m(W*H)

1.Preparation Before The Installation Of Steel Structure Building

The preparation before the installation is what you need to do before you get real started, such as technical, materials, manpower, equipment and some other things, check here out for more details about what you need to prepare before the installation.

2. Inspection Before The Installation Of Steel Structure Building

Inspection before the installation means that you need to do some inspection to the foundation, steel columns & beams, etc, to avoid which may affect the installation process if there is something wrong with them. Check here out for more details about what you need to inspect about the steel components.

3. Column Installation – The Installation Of Steel Structure Building

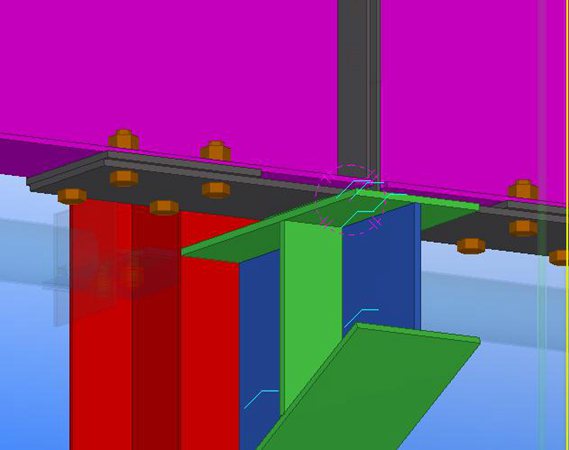

Use a crane to hoist the steel column, one point, or two-point binding. In this case, the columns have corbels, then it is better to bind near the corbel.

Picture 1 Steel Column Hoisting

Picture 2 Steel Column Suspended In The Air

- Binding the column under the corbel with lifting belts, also tie a rope near the column base, which is used to control the movement of the column;

- Lifting the column, draw the column base to the embedded anchor bolts(Picture 1)

- Righting the column when the column base is 30-40mm away from the embedded anchor bolts, align the bolt hole to the anchor bolts, drop the column gradually and make it in position(Picture 2)

Picture 3 Adjust the perpendicularity of the Steel Column

Picture 4 Fasten The Bolts & Welded Together The Bolts And The Steel Column

- Use the theodolite to make the perpendicularity of the column right, usually, the error range is 20mm, after that, fasten the nuts, then untie the lifting belts

- Steel column correction: use the theodolite to test the perpendicularity again, if the error is more than 20mm, then make it right with jack, and jam the gap with steel coil or steel plate(Picture 3)

- Fasten the nuts and then weld the steel base plate together(Picture 4)

- When finished the crane beam and roof beam installation, cast fine concrete in the gap(Picture 5)

Picture 5 Cast Concrete To The Steel Column Base

4. Steel Beam Installation- The Installation Of Steel Structure Building

The installation of the steel beam should follow some order, which is the main beam first and then secondary beam, outside first and inside later, lower beam first and upper beam later.

- Lifting the steel beam up, and guide it into position with the pulling rope, adjust the bolt hole with a crowbar and bolt the beam and column together with the ordinary bolt, the number of bolts should be more than 2 in each joint

- Measure the beam and make sure it is in the right position

- Replace the ordinary bolts with high strength bolts and fasten them

5. Bracing System Installation – The Installation Of Steel Structure Building

When finished the installation of columns and beams, install the tie pipe, supportive bracing, horizontal brace, etc. The bracing system will unite the columns and beams as a whole.

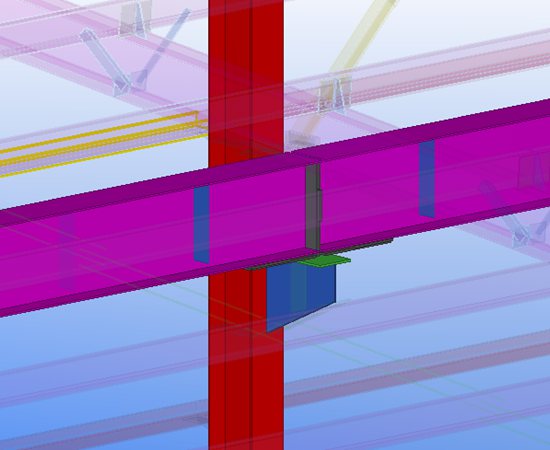

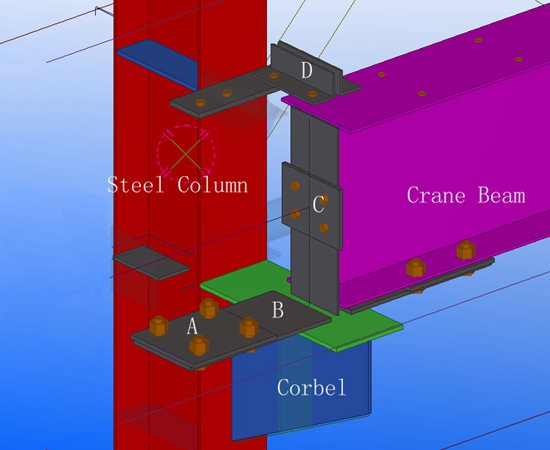

6.Crane Beam Installation- The Installation Of Steel Structure Building

- Weld the spring plate B to the corbel, remember China PEB

- Lifting the crane beam to the right position, put the subplate A between the crane beam and the spring plate B, bolt together the plates(plate A & B) and crane beam

- Connect the crane beam and steel column with angle steel D, and then fasten the bolts

- Connect the two crane beams and fasten the bolts, remember put in the steel plate C between them

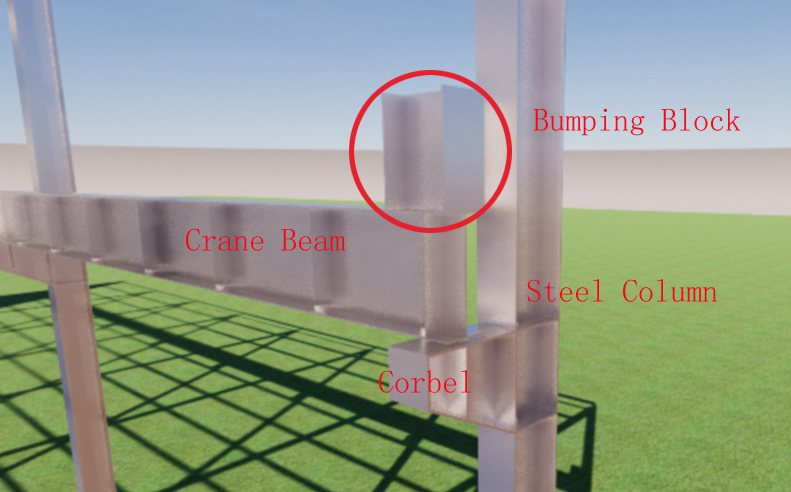

- Bolt (or Weld) the baffle(bumping block) on to the crane beam

7.Overhead Crane Installation – The Installation Of Steel Structure Building

Overhead crane which is also called the electrical single beam crane, is widely used inside of many industrial buildings. Especially common inside of steel structure building, steel structure workshop and steel structure warehouse, maybe steel structure garage. It is convenient than the movable crane and easy than the forklift, and also no need extra space. China PEB is one steel structure company, doesn’t produce overhead crane.

Usually, we don’t provide the crane, instead of that, we would recommend one company if you don’t have one. And you will get the installation instruction from the crane company. Please contact them for details.

8.Wall Purlin Installation – The Installation Of Steel Structure Building

The installation of wall purlin should be after the completion of the supporting system

- The lower wall purlin first, and the top one should be the last one

- Install the pull rod after done with the girder installation, fasten the nuts on both sides, make sure the wall purlin straight

- Weld the vertical wall purlin on the horizontal purlin where have windows and doors

- Clean the welding slag and paint antirust paint and finishing coat

9.Roof Purlin Installation – The Installation Of Steel Structure Building

Same as the installation of the wall purlin, start from the lower one or the one on the ridge, fasten the nuts and install the pull rod.

10.Wall Panel Installation – The Installation Of Steel Structure Building

Install the front wall panels or the back wall panels first, then the gable wall panels

- According to the wall panel layout from China PEB, put the right length panel in the right position

- Screw it down to the purlin from top to the bottom, and at least 3 screws for each purlin

- When all the panels are done, then cut the panels which block the windows and doors

- Cut the gable wall panels along the slope

- Install the edge sheet to the window opening and door opening, and apply a sealant to the joint

- Put on the windows and doors, and screw it down onto the purlin

- Carry out the sealant when finishing the installation of windows and doors

- Install the electrical rolling door(see instructions here)

- Tear off the protective film

11.Gutter Installation – The Installation Of Steel Structure Building

Most buildings need gutter and rain pipe except some small industrial buildings, like this workshop, it doesn’t need it.

Materials used for gutter: black steel sheet, color coated steel sheet, galvanized steel sheet, stainless steel coil & sheet, FRP gutter, aluminum alloy gutter. (Know more here)

Installation type:

- Add-on type: this kind of installation limited the weight of the gutter, it should be small and lightweight, for example, gutter made of color coated steel sheet, aluminum alloy gutter, stainless steel coil gutter. It usually fixed on the lowest roof purlin or on the top of the wall panel. And besides that, it also needs some steel strip to pull the outside of the gutter.

- Bracket gutter, if the gutter is large or heavy, it must be installed on the bracket. Use angle steel or steel plate weld on the column or roof beam to bear the weight of the gutter.

12.Roof Panel Installation – The Installation Of Steel Structure Building

Choose the installation direction according to the perennial wind direction, in other words, perennial wind direction is from left to the right, then you should start your installation from the right side, then the left panel will be on the top of the right one, even there is some flaw or maybe some missed screws, it will not be blown away in bad weather.

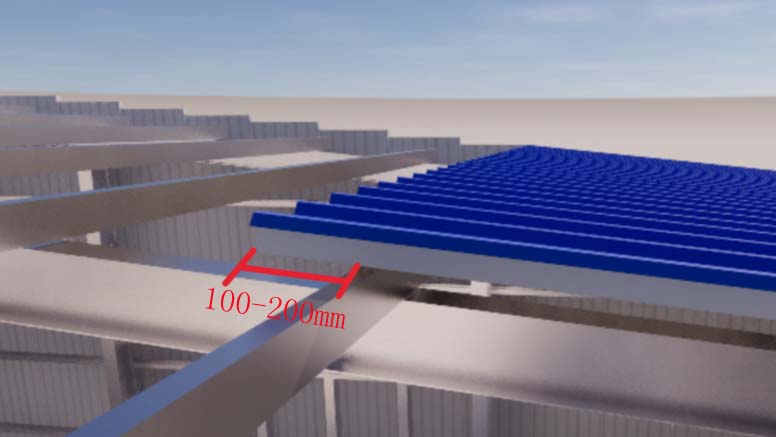

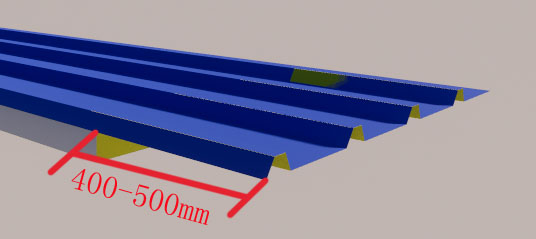

For most buildings, the roof panel length is longer than 12m, but the clear length of the container(40ft container) is around 11.8m, so it has to be cut into two or more pieces. Then you need to know how to splice the roof panels:

- Install the lower part of the roof panel, the top of this part should reach out of the purlin for 100-200mm

- Cut off the inside sheet and core material of the next roof panel for 400-500mm from the bottom, the bottom of the outside steel sheet should reach out the purlin for 150-250mm

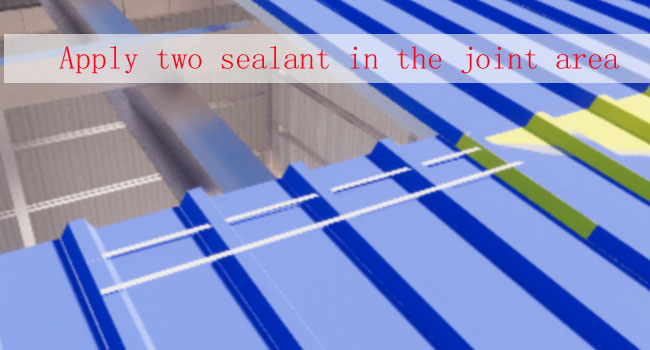

- Apply sealant at intervals of 100mm in the lap area

- Put the top panel on the right position, screw it down

- Use cushions when to screw on the skylight sheet, and make sure the screws on the peak to avoid leaking

- After done with the installation of all the roof panels, install the roof edge and eave edge

- Install the ventilator if you need them(know more here)

- Peel off the protective films

Now you have done all the installation, just contact us if you have more questions.

Leave A Comment