Today steel structure building can be seen everywhere, from workshop to high-rise buildings, there are so many buildings adopt steel structure. Compared with traditional buildings, steel buildings have its own characteristics, for better use of steel structure, here we discuss the advantages and disadvantages.

What is steel structure building?

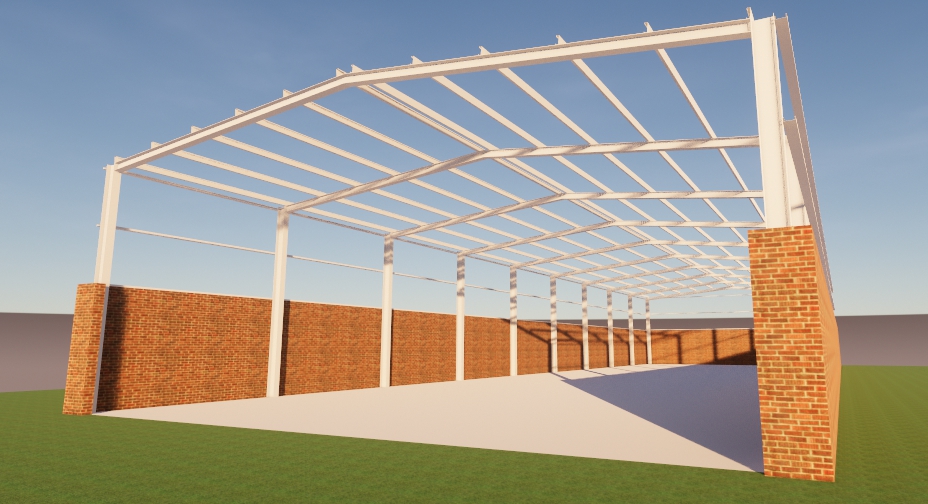

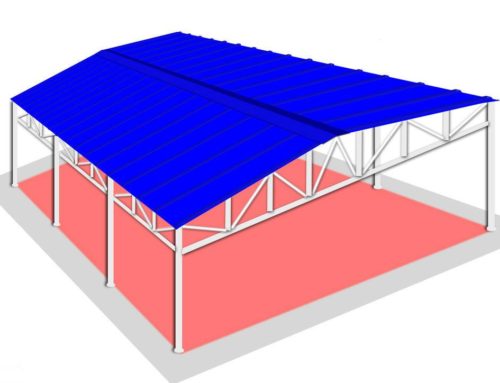

Steel structure building is a kind of building that used the steel skeleton, and profile sheet or glass wool sandwich panel as the enclosure system, now it is one of the major building types. Please check more at steel structure buildings manufactured by China PEB.

Steel warehouse, steel workshop, steel conference room, steel high-rise, steel hangar, steel shed, steel barn, container house, steel prefab house, container prefab house, etc, any building you could build with steel structure, it is more cheap, saving more construction period.

What does the steel structure building consist of?

The steel structure building is consists of structure skeleton, enclosure system, ventilator system, windows & doors.

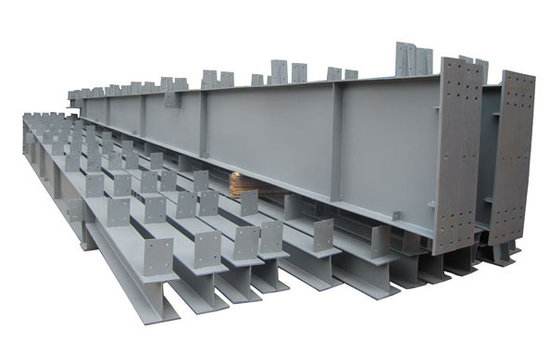

- Structure skeleton is consists of steel columns, steel beams, girders, purlins, tie bars, bracing, etc.

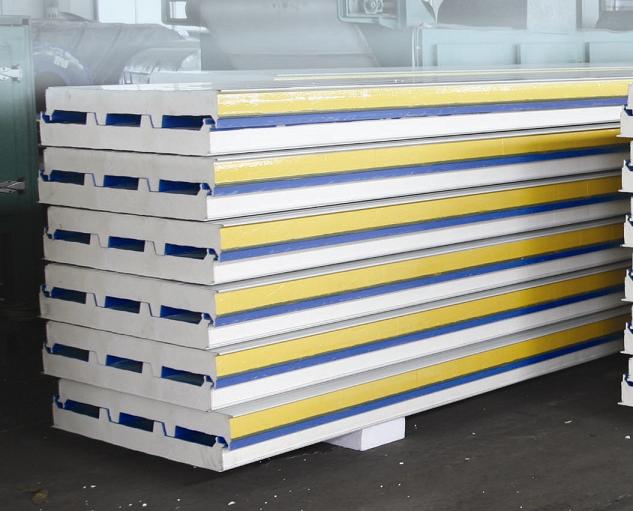

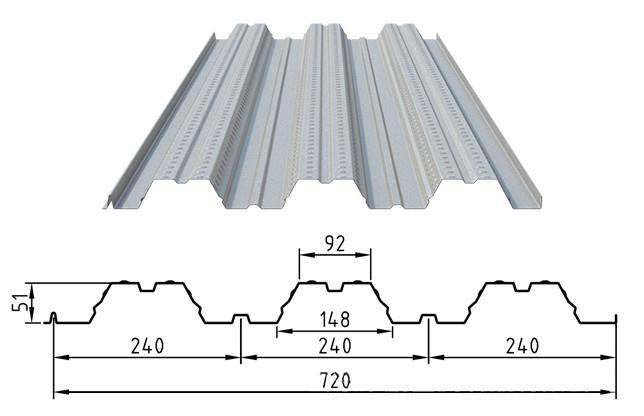

- Enclosure system: profiled steel sheet, rock wool or glass wool, EPS board, sandwich panel

- Ventilator system: axis flow ventilator, motor ventilator, ventilator windows

- Windows & doors: aluminum or PVC windows, roller shutter door, aluminum door

The advantages and disadvantages of steel structure building:

Advantages:

- high strength, lightweight

The material has high strength and high elastic modulus. Compared with concrete and wood, the ratio of density and yield strength is relatively low, so under the same stress conditions, the steel structural components have a smaller cross-section, lightweight, easy to transport and installation, suitable for the large span, big height, significant bearing.

2.Good toughness, good plasticity, uniform material, high structural reliability

Suitable for bearing impact and dynamic load, with good anti-seismic performance. The internal structure of the steel is uniform and is similar to the isotropic homogeneous body. The actual working performance of steel structure is more consistent with the calculation theory. So the steel structure is highly reliable.

3.Steel construction installation of a high degree of mechanization, high construction speed

The steel structure is easy to manufacture in the factory (or workshop), assemble at the site. Factory mechanized steel structure components of high precision, high production efficiency, site assembly fast, short construction period. The steel structure is the best industrialization structure.

4.Low carbon emission, energy saving, green, reusable

The demolition of steel structure building won’t produce waste, steel can be recycled.

Disadvantages:

- Steel structure is ok with heat but will be destroyed in fire

When the temperature below 150 ℃, the steel properties changes very small. So the steel structure can be used for the hot manufacturing workshop, like steel mill production workshop. But when the temperature of steel structure components surface is higher than 150 ℃ heated by the heat radiation, the steel parts need to be isolated with insulation board, such as insulation wool, anti-fire painting, etc. When the temperature is up to 300 ℃ -400 ℃, the strength and elastic modulus of steel will significantly decrease. When the temperature is about 600℃, the strength of steel tends to zero. Buildings which have special anti-fire requirements, the steel structure components(or called steel members) must be protected with anti-fire materials, like concrete, to form the structure of concrete and steel.

- Poor corrosion resistance

Especially in a wet and corrosive environment, steel is easily rust. Generally, steel parts need to use anti-rust painting or galvanized surface, and also need to be maintained regularly. For the offshore platform in the seawater, it needs to use “zinc anode protection” and other measures to anti-corrosion.

Leave A Comment