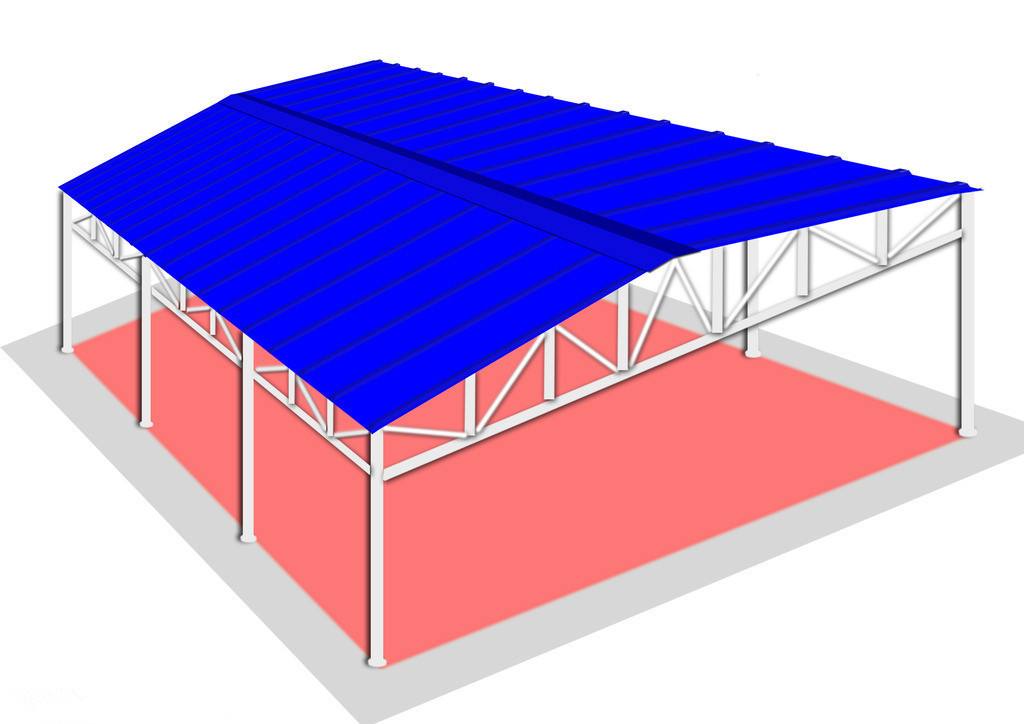

Steel structure shed, is a simple steel structure building, usually used as a canopy, bicycle shed, farms, and other small-scale situation. Usually smaller span, smaller component size, lower cost.

What Is Steel Structure Shed?

Steel structure shed is a sample large-span structure which refers to columns and beams are made of steel components, and the roof usually adopts single color coated steel sheet or plastic sheet, or FRP, or sandwich panels. There is no difference between steel structure shed and steel structure workshop/ warehouse, they have the same structure- portal structure, also some of them use frame structure and some buildings with large span use space truss structure. Generally, there is no wall of this kind of building.

The Uses Of Steel Structure Shed

vegetable markets, carports, rallies, farms, warehouses, planting bases, gas stations and other insulation no special requirements of the occasion.

The Components Of Steel Structure Shed

- The main frame: steel columns, steel beams, space truss

- Secondary components: bracing, corner support, angle support, tie rod

- Purlin: roof purlin, wall purlin

- Connectors: anchor bolts, high-strength bolts, ordinary bolts

- Roof panels: color coated steel sheet, composite panels (EPS, rock wool, glass wool), FRP

- Wall panels: usually don’t use

The Advantages Of Steel Structure Shed

- High material strength, lightweight. Compared with concrete and wood, the same stress smaller cross-section, higher strength, easy to transport and installation, suitable for a large span, large height, and heavy load structure.

- Steel has good toughness and good plasticity characteristics, uniform material, high structural reliability. Suitable for bearing impact and dynamic load, with good seismic performance.

- High degree of mechanization manufacturing, steel components are manufactured in the factory and assemble at the site. The factory mechanized manufacturing of steel structural components finished with high precision and high production efficiency.

- Low cost. Due to the high production efficiency and high mechanization of steel components, the cost of steel is lower than that of concrete and wood.

- Short construction period. The installation of mechanization, small quantity components, dry work, do not need maintenance.

- The wide range of uses: diverse forms of construction, can be widely used in many industries.

- Environmental protection, low carbon, steel can be recycled.

The Disadvantages Of Steel Structure Shed

- The heat-resistant steel structure is not fire-resistant: below 150 degrees, the properties of steel changes very little, when the temperature up to 300-400 degrees, the steel strength and elastic modulus decreased significantly, and when the temperature is600 degrees, the strength of the steel tend to zero. Therefore, in buildings with special fire protection requirements, the steel structure must be protected by fire-resistant materials to improve the fire rating.

- Poor corrosion resistance of steel. Because iron is an active metal, it is easily corrosion in humid and corrosive media environments. Therefore, steel components are generally trusting, corrosion protection (galvanized or painted) and require regular maintenance. For marine platform structures in seawater, a “zinc-anode protection” method is the right choice.

Leave A Comment