What Happened To The Steel Frame?

On 21st July 2021, the group leader of Keren Construction Company was leading 10 workers to install the parapet wall steel columns with 2 cranes according to the schedule of construction. One crane was hoisting the parapet wall steel columns in the area of Axis A cross Axis 14-15, and the other one is working in the area of Axis G cross Axis 15-16.

From 6:30 of that day, steel structure team workers were installing the parapet wall steel columns until 11:30, they continued the installation from 15:30. At 16:34, the wind was rising, at 16:35, part roof panels of No.3 warehouse were blowing off, the steel frame of No. 4 steel warehouse started to lose their shapes, shortly all the steel frames sloped, then the steel frames collapse in less than one second. All the steel frames collapsed on the ground, all the anchor bolts fractured.

This incident causes the death of 5 people.

Brief Introduction Of This Project

This project belongs to a glassware factory, located in Chongqing City, the first phase of construction covers an area of 33141.18 sqm, it consists of warehouse 3, warehouse 4, warehouse 5, and workshop 6. Warehouse 3 covers an area of 19368.5 sqm, three-storey, total height 20.9m; Warehouse 4 covers an area of 6228.71 sqm, one storey, total height 25m; Warehouse 5 covers an area of 1111.91 sqm, one storey, total height 16m; Workshop 6 covers an area of 6432.06 sqm, one storey, a total height of 14.3m.

As warehouse 4 is the building collapse, so here we just introduce the details of warehouse 4.

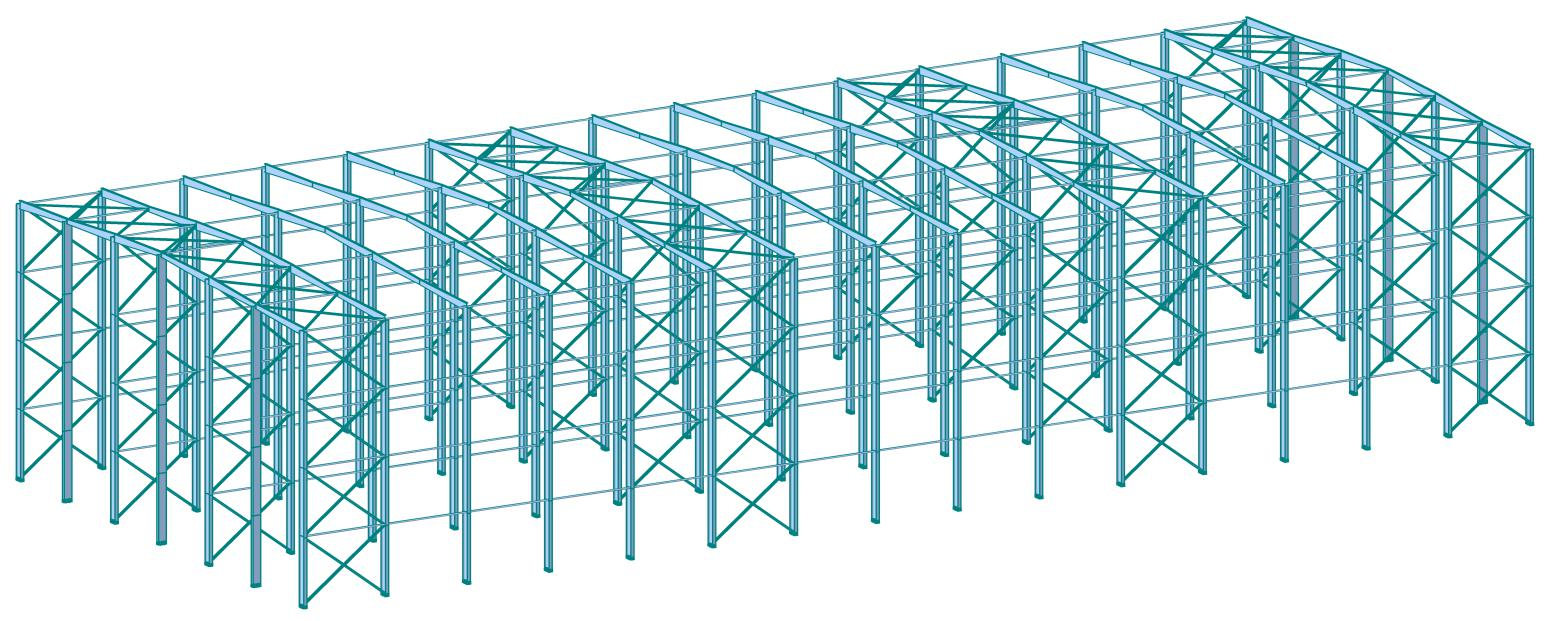

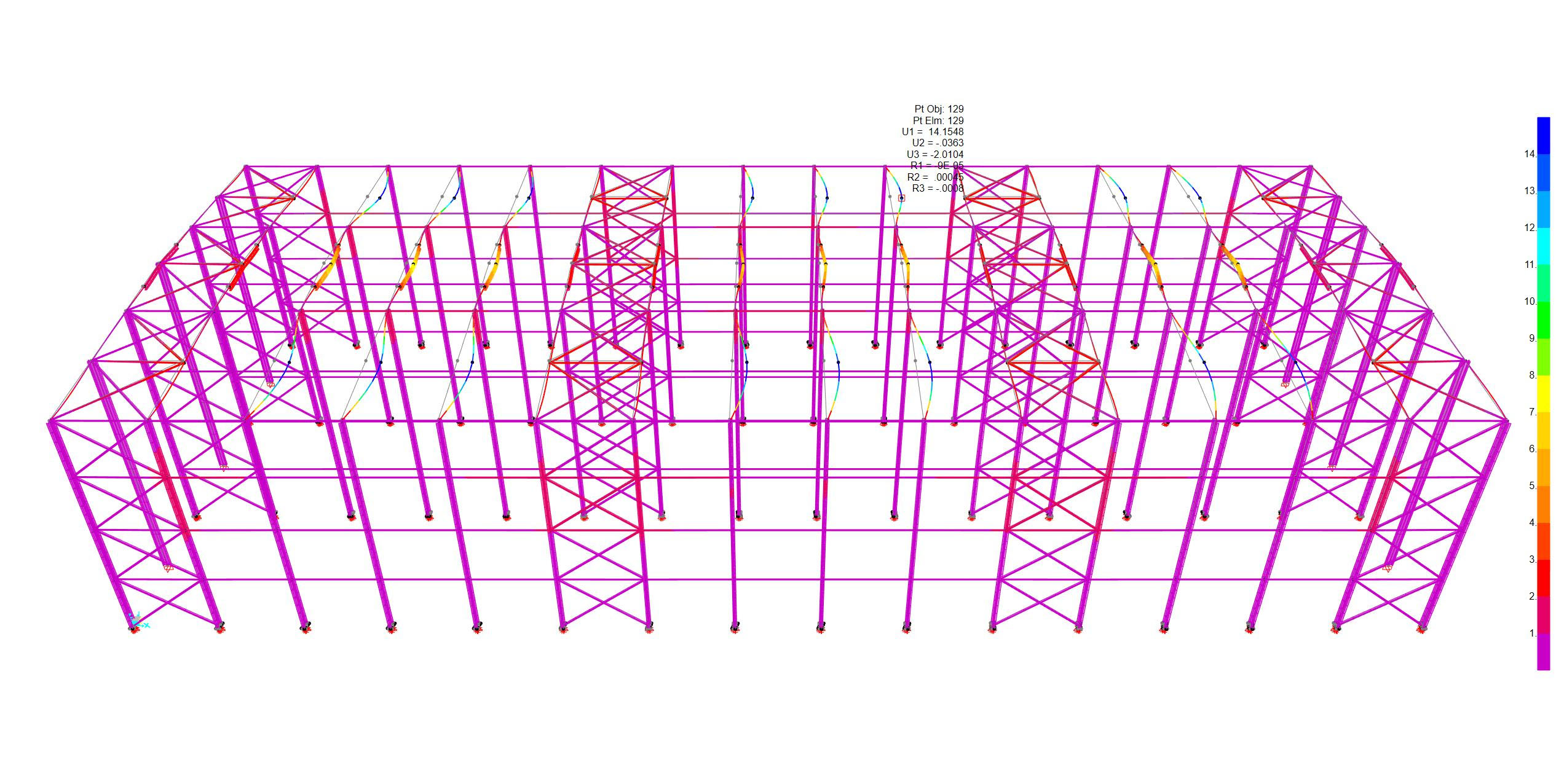

Figure 1, Steel Frame Of Steel Warehouse 120*48*25m

The design information about steel structure warehouse 4

- Dimensions: 120*48*25m(L*W*H)

- Design wind load: 0.4kn/sqm

- Seismic fortification intensity: 6 degrees

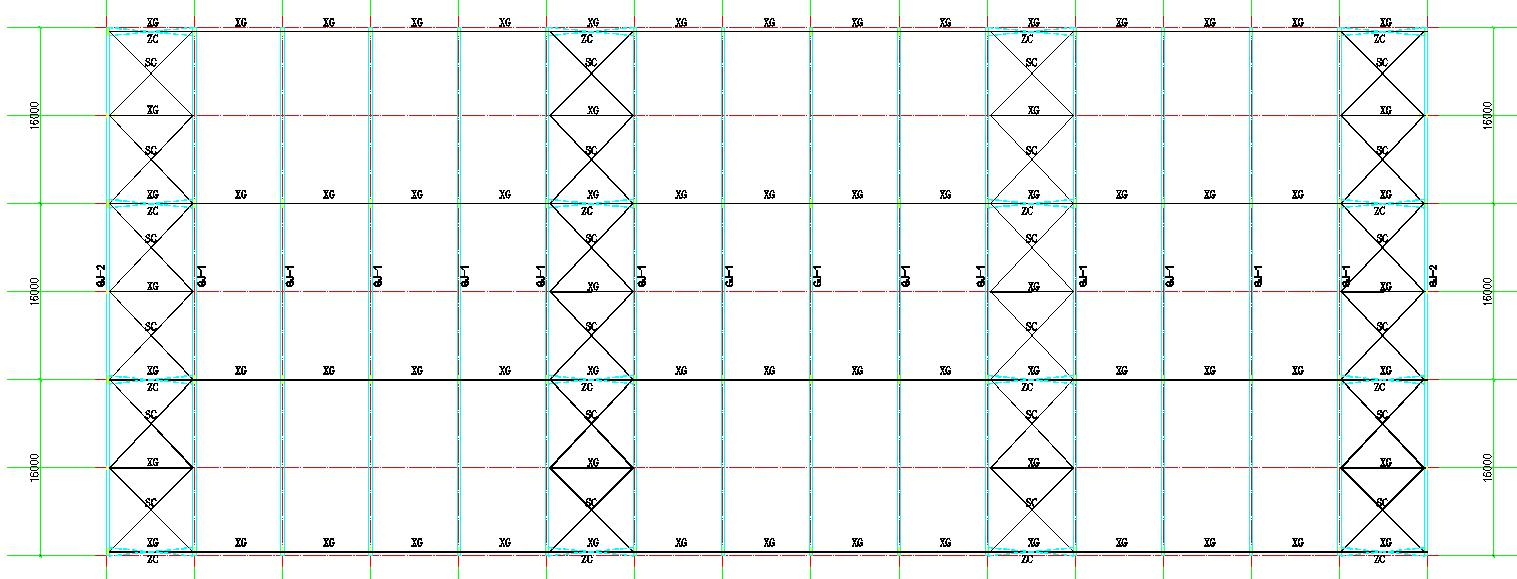

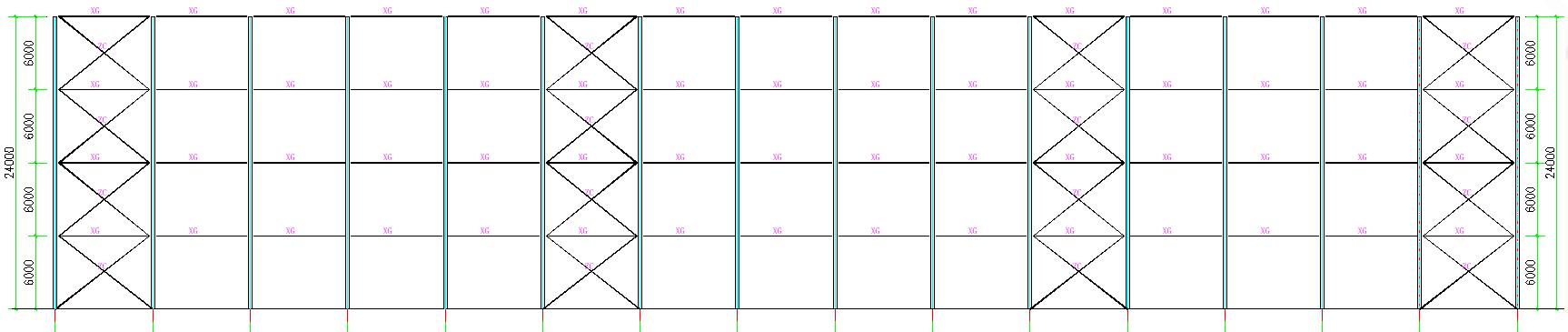

- Lightweight portal structure, axis 1-16 on the long side, column space 8m, axis A – G, column space is also 8m.

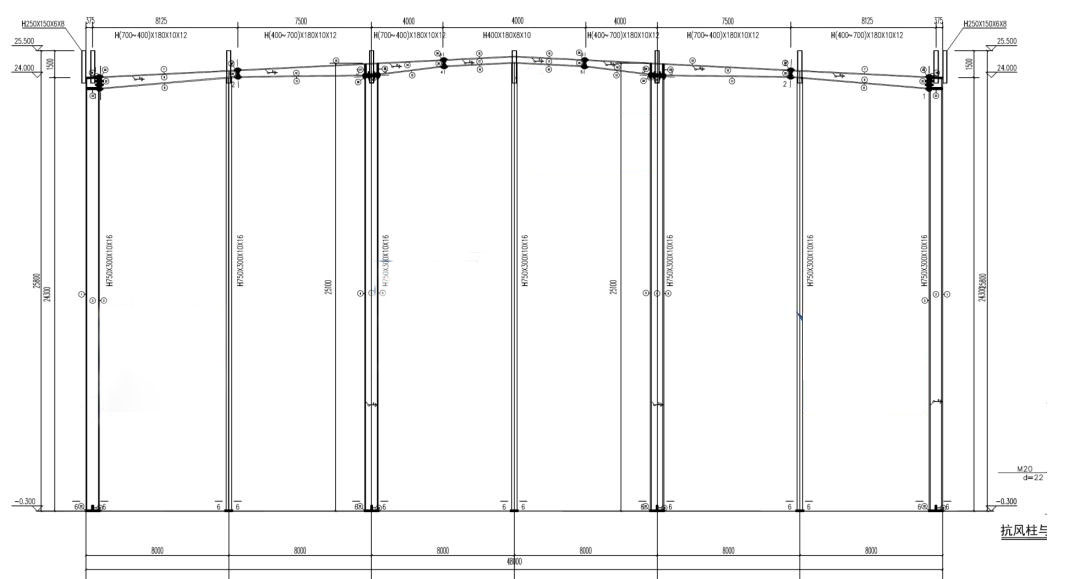

- The cross-section of steel columns is H750*300*10*16; the steel beam is variable section girder, it is H(400-700)*180*10*12, the material is Q355B, which means the yield strength is 355MPa.

- There are four rows of tie bars between columns from bottom to the top, and 4 rows of tie bars arrange between girders, they are all adopted D114*3, Q235B.

- 4 sets of anchor bolts are pre-embedded under each column, D24*900, Q235B, and there are 3 nuts and one steel base plate on each anchor bolt.

- The column base plate above the ground is 50mm, it needs cast concrete after finishing the installation of columns.

- Roof and wall purlin all adopt channel steel C250, Q235B.

Figure 2, Roof Layout Of Steel Warehouse 120*48*25m

Figure 3, Wall Layout Of Steel Warehouse 120*48*25m

Figure 4, Section Drawing To Show The Specifications Of Columns And Beams

Actual construction situation before the accident:

Figure 5, Steel Columns Installation

Before the accident, all the steel columns and steel beams were installed, part of tie bars and parapet columns were installed, column bracing and horizontal bracing were not installed, purlins were not installed, the gap between the ground and column base plate was not cast concrete.

Weather Conditions at the time of the accident:

According to the meteorological record of Chonqing City Observatory, at 16:00 of July 21st, the instantaneous gusty wind at the accident site was level 7-8, the instantaneous wind speed was 14.4-17.7m/s, and the wind direction was 8 degrees from east to south.

According to the basic wind pressure parameters in the Code for Building Structural Load (the basic wind pressure is the wind pressure corresponding to the 10-minute average wind speed that occurs once in 50 years at 10m height under standard geomorphic conditions), the above wind speed observation results are converted by parameters:

At a height of 10m, the wind pressure value from 16:30 to 16:45 is 0.04kN /m2 to 0.05kN /m

Between 2 (wind direction is 98 degrees, 8 degrees from east to south), less than no.4 warehouse design wind load 0.4kN /㎡.

At the time of the accident, the wind direction was 8 degrees from east to south, and the steel frame length direction of No. 4 warehouse was about 30 degrees from east to the south, that is, the wind direction deviated 22 degrees from the steel frame length direction, which was consistent with the basic direction of the collapse of the steel frame.

Accident Cause Analysis

Wind resistance analysis

According to the construction design drawing, site survey records, and relevant national standards and specifications, analysis of the wind resistance of the steel structure was involved in the accident.

According to the design of warehouse 4, under the actual wind load(0.04-0.05KN/sqm), after calculation, the max transformation of the steel structure is 14mm, the max stress of anchor bolts is 16MPa, it is far beneath the yield strength 235MPa, the structure is safe, it won’t collapse during the installation(Figure 6).

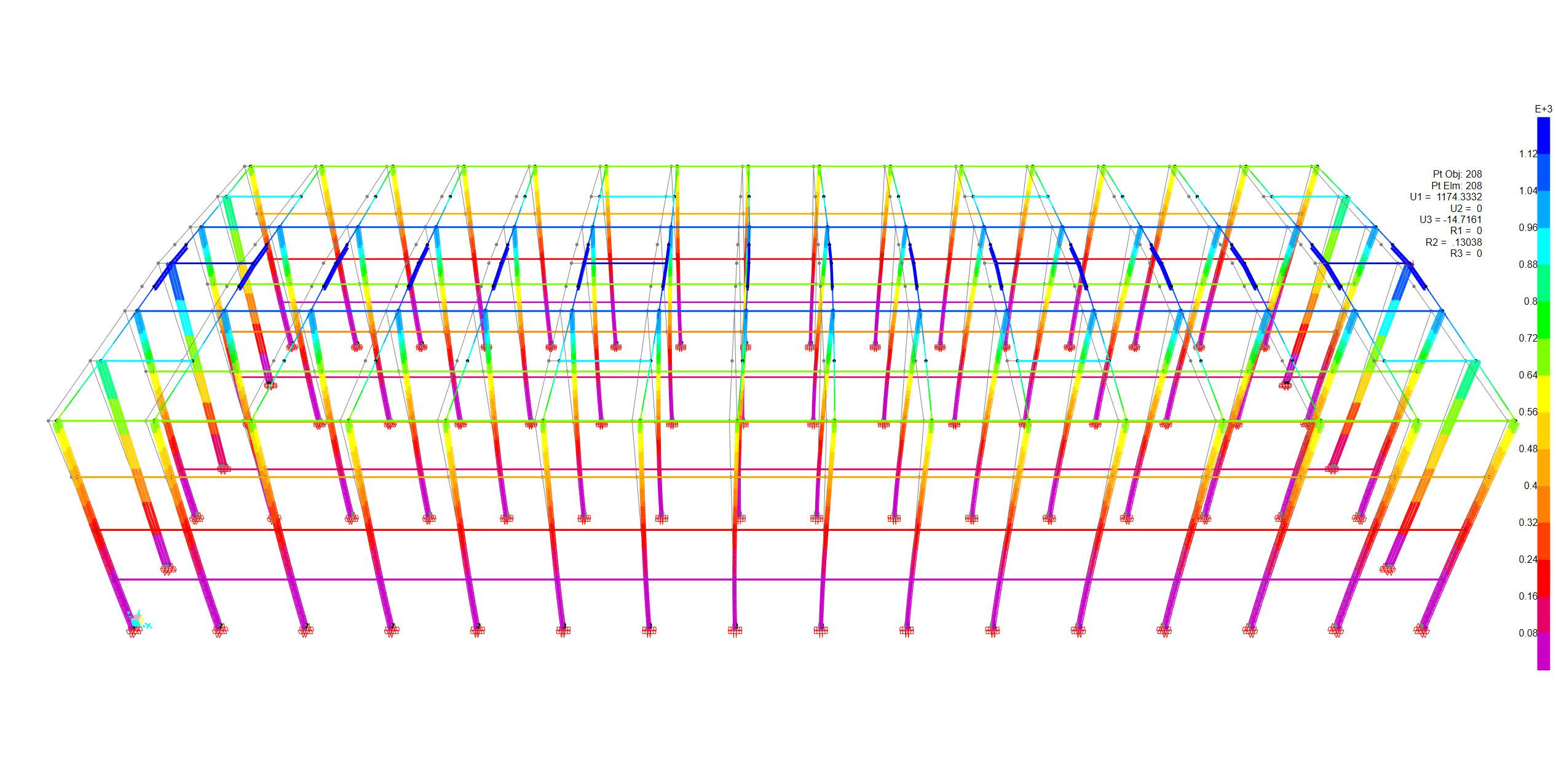

If won’t install the bracing system, won’t case concrete under the column base plate, after calculation, under the same wind load(0.04-0.05KN/sqm), the transformation of this steel structure would be 1174mm, the max tensile stress of the anchor bolts would be 390Mpa, and the pressure stress would be 528Mpa, they both passed the yield stress (235Mpa), the steel structure is not safe(Figure 7).

Figure 6, Steel Frame Force Analysis

Figure 7, Force Analysis Without Bracing System

Figure 8, Steel Column Collapse And Broken The Anchor Bolts

Direct Cause Of The Accident

After the investigation team, combined with the “No.4 Warehouse calculation and analysis report”, “meteorological investigation report” and “accident direct cause analysis expert opinion” and other technical appraisal data, comprehensive determination: the steel structure itself stability is insufficient, induced by a sudden wind, cause the collapse of this steel building.

3.2.1 The steel structure is unstable

According to the “Experts’ Opinion To The Direct Cause Of The Accident”, during the installation of warehouse 4, the workers didn’t install the bracing system (purlin, bracing, etc) in time, only installed part of the tie bars, the steel structure didn’t form a stable rigid structure, also didn’t cast concrete into the gap between column base plate and the concrete base. The steel structure at the site had a certain stability risk and was in an unsafe state.

3.2.2 Outburst Gale

According to the “meteorological research report” & “Calculation Analysis Report Of Warehouse 4”, as this steel structure warehouse lack of bracing system, it is unstable under the wind load and gravity. Under the wind load of 0.04KN/sqm to 0.05KN/sqm at that time, the steel frame transformed a lot, all the anchor bolts were overstressed in tension and pressure, which led to the anchor bolts being unstable and fracture, and finally, collapse all the structure.

Figure 8, All The Steel Frames Collapse

Indirect Cause Of The Accident

3.3.1 The construction company didn’t work according to the technical specifications. The workers didn’t install the bracing system after finishing the installation of the steel columns and beams, which made the steel frame unstable.

3.3.2 The supervision company didn’t supervise according to the codes, didn’t pause the construction when the construction company work against job regulation.

Advices From China PEB

Work with a qualified steel structure company, make sure the design is OK, test the materials and measure the steel components, make sure they are manufactured as the design drawings.

Work with qualified steel structure installation team, make sure they work under the regulations and codes.

Supervise the installation, pause the construction if something goes wrong with the design.

Contact China PEB for more advice.

Leave A Comment